Hubei Ruiyuan Electronic Co.,Ltd.

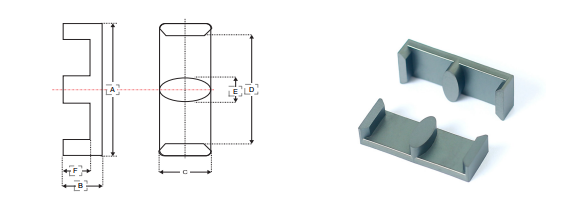

EED CORES

Classification:

High-Frequency Low-Loss Properties: Exhibit minimal core loss under high-frequency operation (≤3 MHz), ideal for medium-to-high-frequency energy conversion systems

High Permeability: High initial permeability (μi:1500–15000)

Contact:

Features

● High-Frequency Low-Loss Properties: Exhibit minimal core loss under high-frequency operation (≤3 MHz), ideal for medium-to-high-frequency energy conversion systems

● High Permeability: High initial permeability (μi:1500–15000)

● High Saturation Flux Density(Bs): 400–550 mT

● wide temperature range: -40°C to +125°C

● Low Coercivity Hc

Applications

● Switch-Mode Power Supplies (SMPS)

● Inverters & UPS

● Common-Mode Filters

● Broadband Transformers

● Vehicle Power Modules

● Magnetic Sensor Circuits

● RF Front-End Components

● Pulse Transformers

● Wireless Charging Systems

● EMI Suppression Beads

Parameter

EED CORES Dimensions

| Type | A(mm) | LB(mm) | csmm) | LD(mm) | E(mm) | F(mm) | B-F(mm) | Weightig(g/Vice) |

|

EOC21 (EED2125) |

212±0.4 | 126±02 | 7,75+0.15 | 162±0.3 | 5.8±0.15 | 9.8±0.2 | 12.8±0.2 | 121 |

| EED3614 | 36.5±0.5 | 74±0.2 | 14.0±0.3) | 30.2±0.4 | 6.0±0.25 | 45-02 | 29-015 | 23.5 |

| EED3814 | 38.0±0.5 | 7.15±0.15 | 140±0.25 | 32,2±0.5 | 60±02 | 4,35±0.15 | 28±0.15 | 24.21 |

| EED4214 | 427±0.51 | 715+015 | 15.0+02/-0.3 | 36,2±0.5 | 70±02 | 4.3+02/-0.1 | 28+0.15 | 28.5 |

| EED4314 | 43.6±0.5 | 7.4±0.2 | 16.0±03 | 37.0±0.41 | 7.4±0.25 | 4.6±0.2 | 28±0.15 | 31.5 |

| EED5214 | 52.0±0.6 | 76±0.15 | 26.9±021 | 43,4±0.61 | 10.6±0.3! | 485±0.2 | 275±0.15 | 67.41 |

Electrical Characteristics

| Type | Core Parameters | ALvalue nH/N2±25% | |||||||

| ci(mm-1) | Le(mm) | Ae(mm2) | Ve(mm3) | RP40 | RP44 | RP47 | RP90 | RP951 | |

| EED2125 | 1.57 | 581 | 36.96 | 2147 | 1500 | 1500 | 1550 | 1550 | 2050 |

| EED3614 | 0.69 | 51.5 | 74.2 | 3824 | 3050 | 3050 | 3200 | 3200 | 42501 |

| EED3814 | 0.72 | 539 | 744 | 4012 | 2700 | 2700 | 2800 | 2800 | 3750 |

| EED4214 | 0.68 | 578 | 84.7 | 4896 | 2900 | 2900 | 3100 | 3100 | 4000 |

| EED4314 | 0.65 | 59.44 | 90.99 | 5409 | 3050 | 3050 | 3200 | 3200 | 4250 |

| EED5214 | 0.36 | 633 | 173.5 | 10990 | 5900 | 5900 | 6200 | 6200 | 8200 |

Keyword:

EED CORES

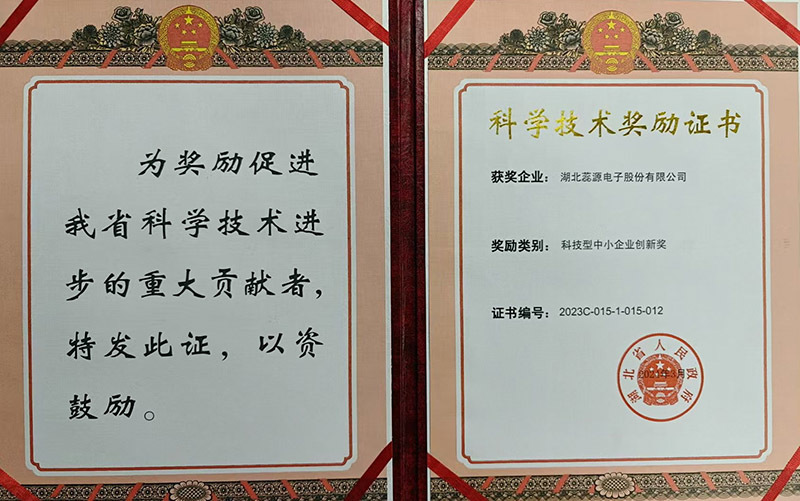

QUALIFICATIONS

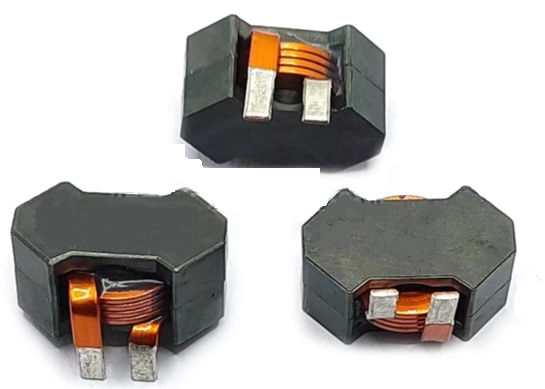

RELATED PRODUCTS

FAQ

Q

How do you maintain a long-term and good business relationship with us?

+

A

We ensure consistent quality and competitive pricing to guarantee our customers' benefits.

We treat every customer as a friend, conducting business with sincerity and building friendships, regardless of their origin.

Q

What is your delivery time?

+

A

Usually, it takes 7 to 15 days for order preparation after receiving your deposit, and shipment is generally completed within 20 days. For standard products, we always have stock available for immediate delivery. However, customized products require more time, depending on your order specifications.

Q

What are the payment terms?

+

A

Typically, a 30% deposit is required in advance, and the remaining 70% balance should be settled before shipment. A 100% irrevocable letter of credit (L/C) at sight, under mutually agreed terms, is also acceptable.

Q

Can I put my label/logo on your products? Do you offer OEM services?

+

A

Yes, we welcome all forms of cooperation. Ruixin can provide customized products based on customer requirements, and both OEM and ODM services are available.

Q

How do you ensure your product quality?

+

A

We have extensive OEM experience serving both domestic trading companies and overseas clients. Our team includes experienced engineers, and we operate standardized production lines. All products comply with the ISO9000 quality system and are certified under the IATF 16949 system.

Q

Manufacturer or trading company?

+

A

We are a manufacturer of nickel-zinc ferrite cores, manganese-zinc ferrite cores, inductors, and high-frequency transformers, with 18 years of experience. As a manufacturer, Ruixin is committed not only to providing high-quality, high-performance, and competitive products but also to on-time delivery and round-the-clock after-sales service.

FACTORY

LEAVE A MESSAGE

For any request of information or technical support, fill in the form. All fields marked with an asterisk * are required.