Hubei Ruiyuan Electronic Co.,Ltd.

NPU's Academician Huang Wei and Professor Wang Xuewen Achieve Series Advances in Specialized Flexible Sensing

Release time:

2025-09-19

Specialized electronics refer to high-reliability, unconventional flexible electronic materials, devices, and systems designed for extreme environments such as aerospace, maritime, polar, and plateau applications.Specialized flexible sensing technology, which integrates flexible electronics and specialized sensing principles, is a key innovation that overcomes the limitations of conventional flexible sensors in extreme environments. It enables reliable acquisition and perception of multi-dimensional information, providing core support for intelligent monitoring and precise control in extreme scenarios.

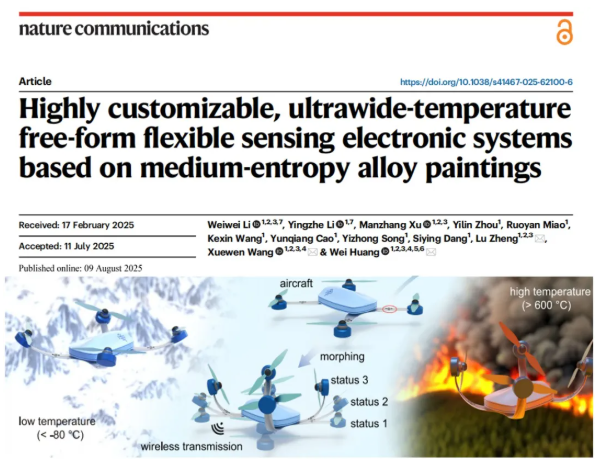

Fig. 1 Specialized Flexible Sensing for Cross-Temperature-Range Monitoring of a Morphing UAV

Recently, the research group led by Academician Huang Wei and Professor Wang Xuewen at Northwestern Polytechnical University (NPU) has achieved a series of advances in specialized flexible sensing.To address bottlenecks like narrow temperature tolerance and low strain sensitivity in flexible strain sensors, the team created a printable high-temperature-resistant medium-entropy alloy ink based on a single-phase Nb-Mo-W solid solution. They innovatively proposed an in-situ heterogeneous printing technique, enabling the direct fabrication of high-performance flexible sensors on arbitrary substrates.The developed flexible sensor successfully breaks through operating temperature limits, challenging the long-held industry belief that "flexible sensors cannot operate stably in high-temperature environments."It also demonstrates exceptional performance in core metrics: its strain gauge factor across an ultra-broad temperature range (-150°C to 1100°C) exceeds that of traditional metal-based and ceramic-based (non-flexible) sensors by over two orders of magnitude.The research team discovered that a cross-scale synergistic mechanism—unique to medium-entropy alloys—governing lattice distortion, nanoparticle spacing modulation, and thin-film stress concentration is the key to achieving these advantages.Based on this achievement, the team validated the real-time and stable monitoring capability of the specialized flexible sensor for the attitude and configuration of a morphing aircraft under extreme temperatures. The related findings were published in Nature Communications (Nat. Commun., 2025, 16, 7351).

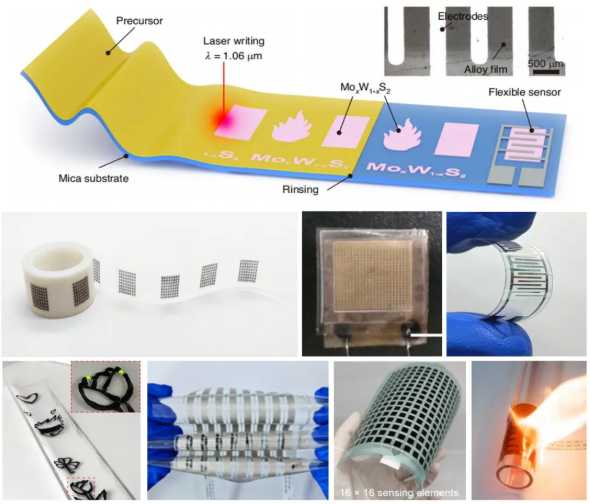

Addressing challenges such as poor high-temperature stability and slow response in flexible sensors, the team proposed an alloying and multi-interface fusion strategy. Using inkjet printing and hydrogen-assisted thermal annealing, they directly fabricated a specialized flexible temperature sensor based on 2D transition metal dichalcogenide (TMDC) alloy thin films on flexible substrates. The sensor achieved stable and transient temperature response across an ultra-wide range (-253°C to 800°C), with a response time as low as microseconds (Research, 2024, 7, 0452);Building on this, the team employed laser direct writing to fabricate 2D transition metal dichalcogenide (TMDC) alloy thin films, revealing their thermal decomposition and in-situ growth mechanisms. This enabled the controllable preparation of high-performance flexible strain sensors, validated for high-frequency vibration detection at 500°C (Microsyst. Nanoeng., 2025, 11, 161).Furthermore, the team employed the zwitterionic surfactant cocamidopropyl betaine (CAB) as a dispersant to develop a fully-printed, multifunctional flexible sensor based on a 2D material architecture (Sci. China Mater., 2025, doi: 10.1007/s40843-025-3470-6).To further break through the performance bottlenecks of flexible strain sensors, the team innovatively proposed an interface enhancement effect based on a zebra-crossing structure, significantly improving the sensitivity of flexible bending sensors.Through array integration, the specialized flexible sensor successfully demonstrated its capability to accurately reconstruct the 3D strain distribution and bending morphology of planar structures (ACS Sens., 2025, 10, 4896).These findings will provide solid technical support for advancing the application of flexible electronics in aerospace, high-end manufacturing, extreme environment monitoring, and related fields.

Fig. 2 Specialized Flexible Strain, Temperature, and Pressure Sensors with Sensor Arrays

This work was supported by the National Key R&D Program, National Natural Science Foundation of China, Fundamental Research Funds for the Central Universities, and Open Testing Fund of NPU Analytical and Testing Center.

In recent years, the group has conducted research on specialized flexible sensing materials and devices, publishing over 80 papers in top international journals including Nat. Commun. (3), Adv. Mater. (9), J. Am. Chem. Soc. (2), and Research (3), with over 10,000 citations. The team has obtained 15 Chinese invention patents and 1 U.S. patent.The research group focuses on the field of "specialized electronics," continuously exploring innovative approaches to talent development in the emerging interdisciplinary field of flexible electronics, pushing the application boundaries of specialized flexible sensing under extreme conditions, and seeking intelligent solutions for national strategic applications of flexible electronics.

Citation: China Electronic Components Association.

Retrieved from http://www.ic-ceca.org.cn

Online Message