Hubei Ruiyuan Electronic Co.,Ltd.

Advances in Bidirectional High-Thermal-Conductivity Graphite Films

Release time:

2025-06-28

With the trend toward high-performance and miniaturized electronic devices, thermal management issues arising from increasing chip power density have become a critical bottleneck limiting device stability.Typically, carbon-based high-thermal-conductivity materials exhibit in-plane thermal conductivity exceeding 1500 W/m·K, while their through-plane thermal conductivity generally remains below 8 W/m·K, making them inadequate for meeting the three-dimensional heat dissipation requirements of high-power devices.

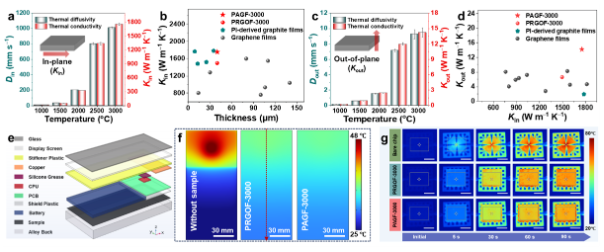

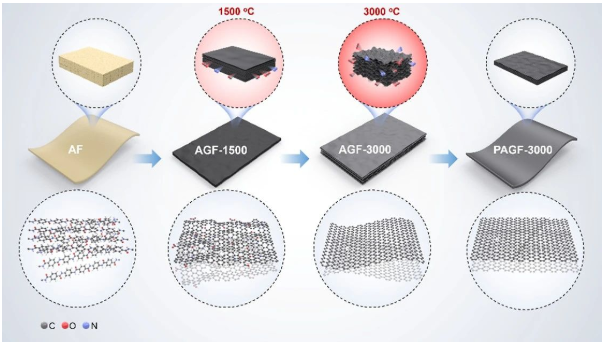

To address these challenges, researchers from the Shanghai Institute of Microsystem and Information Technology (Chinese Academy of Sciences) and Ningbo University proposed a novel approach using aramid films as precursors. Through high-temperature graphitization, they fabricated low-defect, large-grain, and highly-oriented bidirectional high-thermal-conductivity graphite films. Remarkably, these 40-μm-thick films achieved an in-plane thermal conductivity (K<sub>in</sub>) of 1754 W/m·K and a through-plane thermal conductivity (K<sub>out</sub>) reaching 14.2 W/m·K.

Conventional graphite film fabrication using graphene oxide or polyimide precursors often faces structural defect challenges caused by gas evolution. This study innovatively employs aramid films as precursors, leveraging their low oxygen content and nitrogen doping characteristics to enable defect self-healing, grain orientation control, and optimized gas release during 3000°C graphitization.Simultaneously, the nitrogen atoms in aramid facilitate lattice defect healing, yielding bidirectional high-thermal-conductivity graphite films with an exceptionally low defect index (ID/IG ratio of 0.008) after annealing. Moreover, the ordered benzene rings in aramid molecules serve as growth templates for graphite lattices, enabling an in-plane grain size of 2179 nm and through-plane ordered stacking thickness of 53 nm.The study demonstrates that the structurally-engineered bidirectional high-thermal-conductivity graphite film exhibits exceptional anisotropic thermal properties: achieving an in-plane thermal conductivity (K<sub>in</sub>) of 1754 W/m·K (17% enhancement over graphene oxide-derived films under identical conditions) while breaking through the out-of-plane conductivity barrier for carbon-based films with K<sub>out</sub>=14.2 W/m·K (118% improvement). Remarkably, the turbostratic stacking ratio is reduced to just 1.6%, approaching the ideal AB stacking configuration of graphite.

Compared with conventional thermal films, the bidirectional high-thermal-conductivity graphite film demonstrates superior performance in both in-plane and through-plane thermal conductivity as well as defect control. In smartphone thermal simulation tests, the maximum chip surface temperature was reduced from 52°C to 45°C when implementing this advanced graphite film.Furthermore, under extreme thermal conditions (2000 W/cm² heat flux) for high-power chip cooling, the AGFs (advanced graphite films) reduced the chip surface temperature gradient from 50°C to just 9°C, achieving rapid thermal homogenization.

This study reveals the unique advantages of aramid precursors in graphite film fabrication, demonstrating that nitrogen doping and low-oxygen-content precursors can significantly enhance both crystalline quality and bidirectional thermal conductivity. These findings provide critical material solutions and technological support for thermal management in high-power devices such as 5G chips and power semiconductors.

Recently, these research findings were published in Advanced Functional Materials under the title 'Bidirectionally High-Thermally Conductive Graphite Films Derived from Aramid for Thermal Management in Electronics'. The study received support from the National Natural Science Foundation of China and other funding agencies.

Thermal Conductivity of Bidirectional High-Thermal-Conductivity Graphite Films and Their Application in Electronics Thermal Management

Schematic of the Fabrication Mechanism for Bidirectional High-Thermal-Conductivity Graphite Films

Citation: China Electronic Components Association.

Retrieved from http://www.ic-ceca.org.cn

Online Message