Hubei Ruiyuan Electronic Co.,Ltd.

Cost-Effective AI-Driven Design and Development of Rare-Earth Permanent Magnet Materials

Release time:

2025-06-07

NdFeB permanent magnet materials are widely used in new energy vehicles, wind power generation, and energy-efficient motors due to their high coercivity and maximum energy product.Currently, high-performance NdFeB materials often rely on scarce and expensive heavy rare-earth elements such as Dy (dysprosium) and Tb (terbium), significantly limiting their large-scale adoption and application.Introducing abundant and low-cost high-abundance rare earths such as La (lanthanum) and Ce (cerium) as substitutes can alleviate critical resource dependence and improve rare earth utilization efficiency.

Group M03 at the Institute of Physics, Chinese Academy of Sciences has long been engaged in research on rare-earth magnetic functional materials (including permanent magnets and magnetocaloric materials). Pioneering the use of intermediate products from rare-earth separation processes, the group developed the world's first preparation method for high-abundance mixed rare-earth sintered magnets, successfully fabricating high-performance MM(Ce)-Fe-B/Nd-Fe-B dual-main-phase magnets with excellent magnetic properties.Further studies reveal that introducing high-abundance rare earth elements tends to degrade magnet performance.Meanwhile, the increased compositional variables lead to more complex property-composition relationships, rendering traditional trial-and-error optimization strategies inefficient and cost-prohibitive.

Recently, under the joint supervision of Associate Researcher Wang Jing, Researcher Hu Fengxia, and Academician Shen Baogen, Ph.D. candidate Wang Zheng from Group M03 at the State Key Laboratory of Magnetism (Institute of Physics, Chinese Academy of Sciences/Beijing National Research Center for Condensed Matter Physics), in collaboration with Professor Zhu Minggang and Academician Li Wei from the Central Iron & Steel Research Institute, proposed an innovative data-driven material optimization framework employing machine learning. They developed a dual ensemble regression model capable of bidirectional prediction between 'composition + composite electronegativity' and magnetic properties.The research team constructed a comprehensive dataset of melt-spun NdFeB ribbons, incorporating electronegativity, chemical composition, and magnetic properties parameters from published experimental data. By developing model features based on the chemical electronegativity of constituent elements, they mapped raw chemical compositions to a more physically meaningful feature space. This approach enhances model interpretability and provides new insights for optimizing NdFeB material performance.Concurrently, the team incorporated heuristic intelligent optimization algorithms and ensemble strategies. By fusing multiple regression models based on model selection results for different magnetic properties, they further enhanced prediction accuracy and generalization capability. This approach enables efficient development and design of high-abundance rare-earth NdFeB permanent magnets.

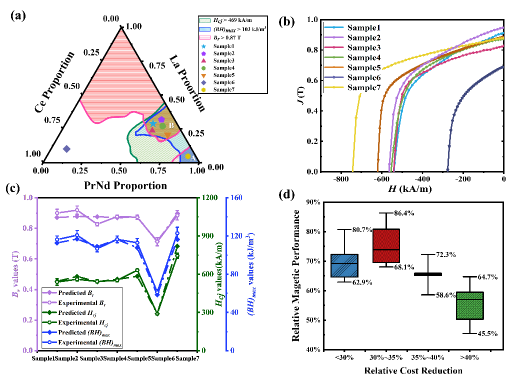

Based on predictive analysis using the established machine learning model, the team identified a composition range within the ((Pr,Nd)xLayCe1-x-y)12Fe82B6 system that combines high magnetic performance with a high proportion of high-abundance rare earth elements. This optimal composition contains 25-40% La and up to 20% Ce of total rare earth content.Experimental validation confirmed the model's prediction accuracy exceeds 90%. Building on this, the team identified four cost-effective NdFeB compositions, all achieving over 28% cost reduction while maintaining >80% of magnetic performance.The optimal composition, (Pr,Nd)8.1La3.6Ce0.3Fe82B6, achieved a 31.3% cost reduction compared to the La/Ce-free baseline while retaining 86.4% overall magnetic performance, demonstrating an exceptional balance between performance and cost-effectiveness.

These findings were published in Acta Materialia [Acta Mater. 2025, 292, 121031] under the title 'Machine learning guided design of RE-Fe-B (RE=Pr,Nd,La,Ce) with comprehensive high performance'.A patent has been filed for this work (Patent No.: 2024105047807). This research was supported by the National Key R&D Program of China (Ministry of Science and Technology), the High-Quality Development Special Fund Project (Ministry of Industry and Information Technology), the National Natural Science Foundation of China, and the Strategic Priority Research Program of the Chinese Academy of Sciences.

Fig. (a) ML-predicted high-performance range;(b) Experimental demagnetization curves;(c) Prediction vs. Experiment;(d) Cost vs. performance trade-off

Citation: China Electronic Components Association.

Retrieved from http://www.ic-ceca.org.cn

Online Message